| TYPE | Metric System Specifications | Inch Specifications | Hose inner diameter I.D | Outer diameter of reinforcement layer W.D | Outside diameter of hose O.D | Thickness of outer rubber layer | Max.W.P | P.P | Min.B.P | Min.B.R | W.T | ||||

| SIZE | SIZE | Min | Max | Min | Max | Max | Min | Max | |||||||

| MM | IN | in | mm | mm | mm | mm | mm | mm | Mpa | Mpa | Mpa | mm | kg/m | ||

| 03-1 ST | 5 | 3/16 | 4.6 | 5.4 | 9.0 | 10.0 | 13.5 | 0.8 | 1.5 | 25.0 | 50.0 | 100.0 | 90 | 0.20 | |

| 04-1 ST | 6 | 1/4 | 6.2 | 7.0 | 10.6 | 11.6 | 16.7 | 0.8 | 1.5 | 22.5 | 45.0 | 90.0 | 100 | 0.25 | |

| 05-1 ST | 8 | 5/16 | 7.7 | 8.5 | 12.1 | 13.3 | 18.3 | 0.8 | 1.5 | 21.5 | 43.0 | 85.0 | 115 | 0.31 | |

| 06-1 ST | 10 | 3/8 | 9.3 | 10.1 | 14.5 | 15.7 | 20.6 | 0.8 | 1.5 | 18.0 | 36.0 | 72.0 | 130 | 0.36 | |

| 08-1 ST | 12.5 | 1/2 | 12.3 | 13.5 | 17.5 | 19.0 | 23.8 | 0.8 | 1.5 | 16.0 | 32.0 | 64.0 | 180 | 0.45 | |

| 10-1 ST | 16 | 5/8 | 15.5 | 16.7 | 20.6 | 22.2 | 27.0 | 0.8 | 1.5 | 13.0 | 26.0 | 52.0 | 200 | 0.52 | |

| 12-1ST | 19 | 3/4 | 18.6 | 19.8 | 24.6 | 26.2 | 31.0 | 0.8 | 1.5 | 10.5 | 21.0 | 42.0 | 240 | 0.65 | |

| 16-1 ST | 25 | 1 | 25.0 | 26.4 | 32.5 | 34.1 | 39.0 | 0.8 | 1.5 | 8.8 | 17.5 | 35.0 | 300 | 0.91 | |

| 20-1 ST | 31.5 | 1-1/4 | 31.4 | 33.0 | 39.3 | 41.7 | 47.5 | 1.0 | 2.0 | 6.3 | 13.0 | 25.0 | 420 | 1.30 | |

| 24-1 ST | 38 | 1-1/2 | 37.7 | 39.3 | 45.6 | 48.0 | 54.0 | 1.3 | 2.5 | 5.0 | 10.0 | 20.0 | 500 | 1.70 | |

| 32-1 ST | 51 | 2 | 50.4 | 52.0 | 58.7 | 61.7 | 68.2 | 1.3 | 2.5 | 4.0 | 8.0 | 16.0 | 630 | 2.00 | |

| 03-2ST | 5 | 3/16 | 4.6 | 5.4 | 10.6 | 11.6 | 16.7 | 0.8 | 1.5 | 41.5 | 83.0 | 166.0 | 90 | 0.32 | |

| 04-2ST | 6 | 1/4 | 6.1 | 7.0 | 12.1 | 13.3 | 18.3 | 0.8 | 1.5 | 40.0 | 80.0 | 160.0 | 100 | 0.36 | |

| 05-2ST | 8 | 5/16 | 7.7 | 8.5 | 13.7 | 14.9 | 19.9 | 0.8 | 1.5 | 35.0 | 70.0 | 140.0 | 115 | 0.45 | |

| 06-2ST | 10 | 3/8 | 9.3 | 10.1 | 16.1 | 17.3 | 22.2 | 0.8 | 1.5 | 33.0 | 66.0 | 132.0 | 130 | 0.54 | |

| 08-2ST | 12.5 | 1/2 | 12.3 | 13.5 | 19.0 | 20.6 | 25.4 | 0.8 | 1.5 | 27.5 | 55.0 | 110.0 | 180 | 0.65 | |

| 10-2ST | 16 | 5/8 | 15.5 | 16.7 | 22.2 | 23.8 | 28.6 | 0.8 | 1.5 | 25.0 | 50.0 | 100.0 | 200 | 0.80 | |

| 12-2ST | 19 | 3/4 | 18.6 | 19.8 | 26.2 | 27.8 | 32.6 | 0.8 | 1.5 | 21.5 | 43.0 | 85.0 | 240 | 0.94 | |

| 16-2ST | 25 | 25.0 | 26.4 | 34.1 | 35.7 | 40.8 | 0.8 | 1.5 | 16.5 | 32.5 | 65.0 | 300 | 1.35 | ||

| 20-2ST | 31.5 | 1-1/4 | 31.4 | 33.0 | 43.3 | 45.7 | 52.4 | 1.0 | 2.0 | 12.5 | 25.0 | 50.0 | 420 | 2.15 | |

| 24-2ST | 38 | 1-1/2 | 37.7 | 39.3 | 49.6 | 52.0 | 58.8 | 1.3 | 2.5 | 9.0 | 18.0 | 36.0 | 500 | 2.65 | |

| 32-2ST | 51 | 2 | 50.4 | 52.0 | 62.3 | 64.7 | 71.4 | 1.3 | 2.5 | 8.0 | 16.0 | 32.0 | 630 | 3.42 | |

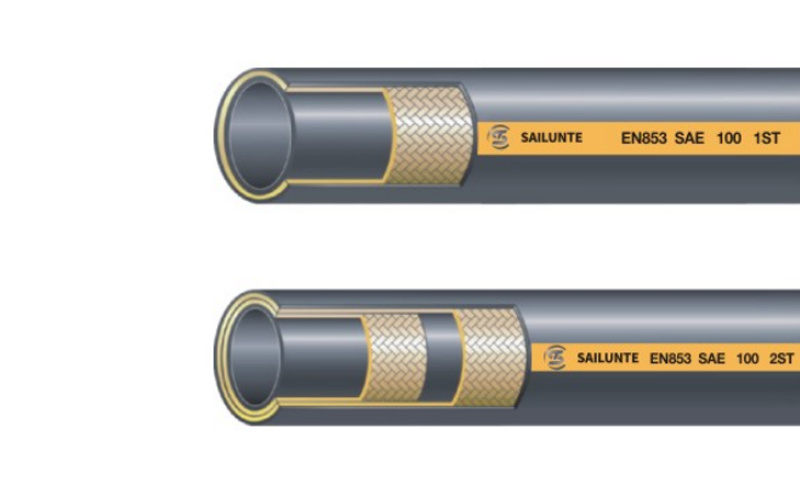

Steel wire braided rubber hose

Application:For the delivery of hydraulic fluids and water-based liquids.

Feature:Manufactured from oil-resistant, anti-aging synthetic rubber with a smooth-finish reinforcement. Complies with DIN EN 853 1ST/2ST and SAE J517 100R1A/100R2A. Working temperature range: –40 °C to +100 °C (–40 °F to +212 °F).

Get a QuoteWhatsApp